CERAMICS

Ceramics is one of Jinxi’s major features. It integrates traditional art and abstract art into its ceramic products. In other words, Jinxi’s ceramic products are all perfect combinations of traditional ceramic art and modern abstract ceramic art. Thanks to its designers’ originality and potters’ craftsmanship, all of its ceramic products are lifelike.

The ingenuity of the craftsmen worked at the process with great care and precision, excel at the creation of superior quality. Presentation of the most exquisite colors required continued refinement of blank manufacturing. The inside information of each work of art originated from the incessant pursuit of refinement. Each step of cut and polishing embodied the inheritance and delivery of art in traditional crafts.

Curing of the bland base posed strict requirements on site selection to avoid cracks resulting from direct sunlight. Every delicate line, shape of the blank and curing conditions for different types produced strict requirements of area, humidity and temperature. Exquisite workmanship featured the shaping of beauty from the very beginning.

With great care and patience, the craftsman carved out and inlaid ears of the earthenware,which needed precision and assurance in each step. Forming the shape of the blank and compositing the basic pattern thereon, the craftsman unified the body and spirit of the work on the wall of the blank, there revealed the pleasant texture of art.

After coloring the trimmed blank and carved the colored lines on the wall, the craftsman polished the base carefully and drew in the lines. With fine strokes in slow and delicate movement, plum blossoms, orchid, bamboo, chrysanthemum and other abstract artistic images stood vividly thereon. Genuine heart of the craftsman has made the details of each colored work of art fine and touching; the beautiful and evocative colored lines only came from careful strokes by hand.

Atomize the glaze slip with spray gun or atomizer and apply it to the surface of the blank. Immerse the blank into the glaze slip for a while and take it out. The water absorption of the blank would help attach the glaze evenly on its surface.

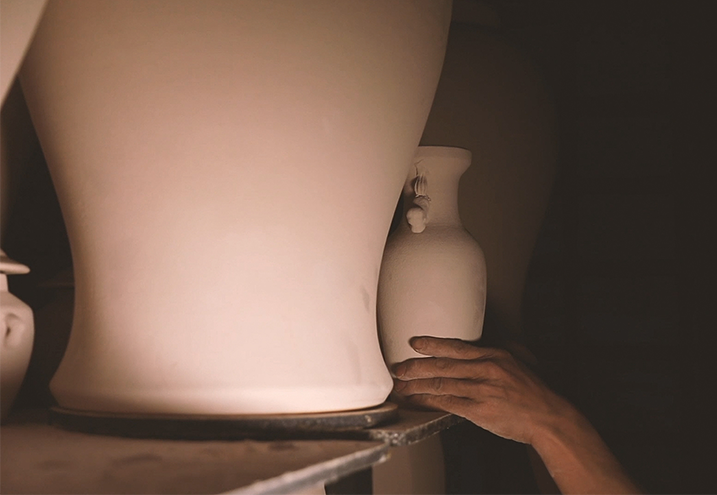

After glazing, polish the edges and then placed it onto the shelf in good order fixed. Each piece of earthenware had its own place. Slowly the workers pushed the shelf into the kiln.

The earthenware was kilned for about one day and night at the temperature of around 1300℃. First build the kiln door, then fire up the kiln and add pine logs as fuel; wait for the delicate ceramic products of Jinxi to finally come out of the kiln. Every pattern thereon was fine and smooth, boasting pure artistic charm.